“`html

Types of Oilfield Accidents and How to Prevent Them (Updated for 2025+)

Estimated reading time: 15 minutes

Key Takeaways

- Oilfield operations are inherently dangerous, requiring proactive safety measures.

- Understanding the root causes of accidents is crucial for effective prevention.

- Technological advancements and human factors play vital roles in enhancing safety.

- Adequate oil and gas insurance coverage is essential for mitigating financial risks.

Table of Contents

- Understanding Oilfield Accidents

- Common Types of Oilfield Accidents

- Root Causes of Oilfield Accidents

- Prevention Strategies: Regulations and Best Practices

- Technological Advancements in Accident Prevention

- The Human Factor: Behavior-Based Safety and Mental Health

- Case Studies: Learning from Past Accidents

- The Role of Insurance in Mitigating Oilfield Accident Risks

- Future Trends in Oilfield Safety

- Conclusion

Oilfield operations, while vital for energy production, are inherently dangerous. Each year, countless oilfield accidents occur, resulting in injuries, fatalities, environmental damage, and significant financial losses. Consider that in 2023 alone, oilfield accidents led to over $5 billion in insurance claims and lost productivity. This guide aims to provide a comprehensive overview of how to identify, prevent, and mitigate these accidents, tailored for 2025 and beyond. By implementing proactive oilfield safety measures, companies can drastically reduce risks and even lower their oil and gas insurance costs.

This post will delve into the common types of accidents, their root causes, and the latest prevention strategies, including technological advancements and the crucial role of human factors.

Understanding Oilfield Accidents

Oilfield accidents can be defined as any unplanned event during oil and gas exploration, drilling, production, or transportation that results in injury, fatality, environmental harm, equipment damage, or economic loss. These incidents range from minor slips and falls to catastrophic events like explosions and well blowouts. The consequences of oilfield accidents extend far beyond immediate physical damage. They can lead to:

- Loss of life and serious injuries: Workers can suffer from burns, broken bones, crush injuries, and long-term health issues due to chemical exposure.

- Environmental damage: Oil spills and gas leaks contaminate soil, water, and air, harming wildlife and ecosystems.

- Business disruption: Accidents halt operations, leading to production delays, legal liabilities, and reputational damage. It’s important to have a plan for business continuity in the event of an accident.

A proactive oilfield safety culture is essential to minimize these risks. This involves implementing robust risk management systems, providing comprehensive training, and fostering open communication about safety concerns.

Common Types of Oilfield Accidents

The oilfield environment presents a variety of hazards that can lead to accidents. Understanding these hazards is the first step in preventing them.

- Well Blowouts: A well blowout occurs when formation pressure exceeds the pressure exerted by the drilling mud, causing an uncontrolled release of crude oil or natural gas. These incidents can result in devastating environmental damage, loss of life, and significant financial losses. The Deepwater Horizon disaster serves as a stark reminder of the potential consequences.

- Causes: Pressure imbalances, equipment failure (especially of Blowout Preventers or BOPs), and human error.

- Consequences: Environmental damage, loss of life, property damage, and legal repercussions.

- Prevention Techniques: Regular BOP maintenance and testing, pressure monitoring, and adherence to well control procedures are vital for blowout prevention. You can read the latest updates on well control regulations from the Bureau of Safety and Environmental Enforcement (BSEE) for further information.

- Confined Space Accidents: Confined space safety is another critical area. Tanks, vessels, and pits can contain hazardous atmospheres, leading to asphyxiation or toxic gas exposure.

- Dangers: Asphyxiation due to oxygen deficiency, exposure to toxic gases (e.g., hydrogen sulfide), and engulfment.

- Regulations: OSHA has specific regulations for confined space entry, requiring permits, ventilation, and atmospheric monitoring.

- Safety Procedures: Continuous atmospheric monitoring using wearable sensors, proper ventilation, pre-entry checks, and rescue plans are essential for safe confined space entry. You can find additional details in OSHA’s resources on confined spaces.

- Dropped Object Incidents: These accidents involve tools or equipment falling from heights, causing injuries or damage.

- Details: Falling tools, equipment, or materials striking workers or damaging equipment.

- Prevention Strategies: Tool tethering, safety nets, regular inspections of equipment, and good housekeeping practices. For example, a series of dropped object incidents on an offshore platform led to the implementation of a tool tethering program, safety netting, and improved housekeeping practices.

- Transportation Accidents: The transportation of heavy equipment, materials, and personnel to and from oilfield sites poses significant risks.

- Risks: Vehicle collisions, rollovers, and incidents involving pedestrians.

- Prevention: Regular vehicle maintenance, driver training, load securement, and adherence to traffic regulations. To prevent transportation accidents, mandatory implementation of driver monitoring systems (DMS) and advanced driver-assistance systems (ADAS) are becoming increasingly important. Learn more about transportation safety and the risks of driver fatigue from the Federal Motor Carrier Safety Administration (FMCSA).

- Chemical Exposure: Oilfield workers are frequently exposed to a variety of hazardous chemicals.

- Health Hazards: Exposure to chemicals like benzene, hydrogen sulfide, and drilling fluids can cause skin irritation, respiratory problems, and long-term health issues.

- Safety Protocols: Proper use of personal protective equipment (PPE), adequate ventilation, and spill response procedures are crucial for preventing chemical exposure. For example, a chemical release incident at a refinery, resulting in multiple worker injuries, prompted a company to implement a comprehensive chemical safety management program.

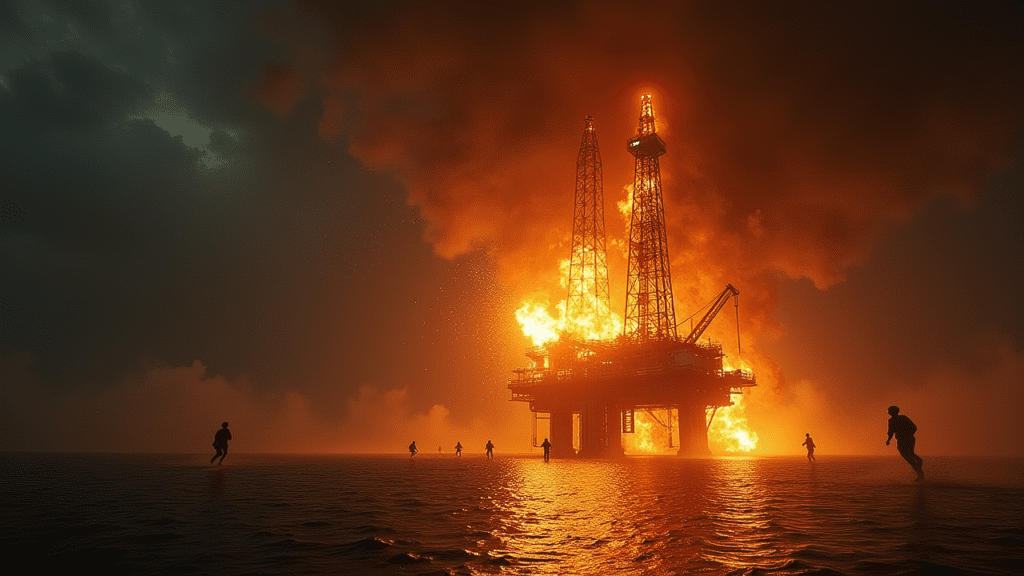

- Fires and Explosions: The presence of flammable materials and ignition sources makes fires and explosions a significant hazard.

- Details: Ignition of flammable gases or liquids, leading to fires or explosions.

- Preventive Measures: Proper ventilation, regular equipment maintenance, spark arrestors, and strict adherence to hot work permits are essential for preventing fires and explosions.

Root Causes of Oilfield Accidents

To effectively prevent oilfield accidents, it’s crucial to understand their underlying causes. Root cause analysis helps identify the factors that contribute to incidents, allowing for targeted interventions.

- Lack of Training: Inadequate or outdated training programs leave workers unprepared to handle hazardous situations.

- Equipment Malfunction: Poor maintenance, aging equipment, or design flaws can lead to equipment failures and accidents.

- Human Error: Fatigue, complacency, communication breakdowns, and failure to follow procedures are significant contributors to accidents. Recent studies indicate that human error contributes to approximately 70-90% of oilfield accidents. The Energy Institute offers valuable resources and insights into this area.

- Procedural Failures: Poorly written or unenforced safety procedures create opportunities for errors and accidents.

- Management Oversight: Lack of leadership commitment to safety can lead to a weak safety culture and inadequate resource allocation for safety programs.

Prevention Strategies: Regulations and Best Practices

Effective accident prevention requires a multi-faceted approach that combines regulatory compliance with industry best practices.

- Regulatory Bodies: Key regulatory bodies include OSHA (Occupational Safety and Health Administration) and BSEE (Bureau of Safety and Environmental Enforcement). These agencies set and enforce safety standards for oil and gas operations. Refer to the official OSHA website and BSEE website for detailed information.

- Key Safety Regulations and Standards: These include standards for well control, confined space entry, hazard communication, and personal protective equipment.

- Best Practices for Accident Prevention:

- Real-time Monitoring Systems: Using sensors and data analytics to predict equipment failures and detect hazardous conditions.

- Enhanced Training Programs: Simulation-based training and virtual reality for realistic scenario training.

- Improved Communication Protocols: Digital communication tools and standardized procedures for clear communication.

- Emergency Response Plans: Comprehensive plans that outline evacuation procedures, medical support, and communication strategies in the event of an emergency.

Technological Advancements in Accident Prevention

Technology plays a crucial role in enhancing oilfield safety and reducing the risk of accidents.

- AI and Predictive Maintenance: Artificial intelligence (AI) algorithms can analyze data from sensors and equipment to predict potential failures and optimize maintenance schedules. Industry reports show a 20-30% reduction in equipment failures with AI-powered predictive maintenance. McKinsey provides further insights on the use of AI in the oil and gas industry.

- Remote Operations and Automation: Remote-controlled equipment and automated systems reduce human exposure to hazards in drilling, production, and inspection activities.

- Drones in Safety Inspections: Drones equipped with cameras and sensors can perform aerial inspections of pipelines, platforms, and other infrastructure, identifying potential hazards quickly and efficiently.

- Digital Twins for Risk Assessment: Digital twins are virtual replicas of physical assets and processes, enabling comprehensive risk assessments and simulations. Increased use of digital twins enables proactive hazard identification. Honeywell offers digital twin solutions to help oil and gas operators improve safety and drive efficiencies.

- Robotics and ROVs: Robots and remotely operated vehicles (ROVs) can be deployed for inspections, repairs, and emergency response in hazardous environments, minimizing human risk. The Society of Petroleum Engineers (SPE) offers resources on robotics applications in the oil and gas industry.

- Cybersecurity: Protecting operational technology (OT) systems from cyberattacks is crucial to prevent physical accidents. Compromised control systems can lead to equipment malfunctions, explosions, and other incidents. The Cybersecurity and Infrastructure Security Agency (CISA) provides resources on industrial control systems security.

The Human Factor: Behavior-Based Safety and Mental Health

While technology plays a vital role, the human factor remains a critical element in oilfield safety.

- Behavior-Based Safety (BBS) Programs: BBS programs encourage employee participation in safety management by observing and providing feedback on safe and unsafe behaviors.

- Mental Health and Worker Safety: Stress, fatigue, and mental health issues can significantly impair worker performance and increase the risk of accidents. Integrating mental health support programs can improve worker alertness and reduce accident rates. The Oil & Gas Council (OGC) offers insights on industry best practices related to worker well-being.

- Wearable Technology for Worker Safety: Wearable devices can track worker location, detect falls, monitor vital signs, and provide real-time alerts in hazardous situations.

Case Studies: Learning from Past Accidents

Analyzing past oilfield accidents provides valuable lessons for preventing future incidents.

- Deepwater Horizon Disaster: This catastrophic well blowout highlighted the consequences of inadequate safety measures, particularly with blowout preventers.

- Chemical Release Incident: A chemical release incident demonstrated the importance of comprehensive chemical safety management programs.

- Dropped Object Incidents: These incidents illustrate how a targeted approach can improve safety by implementing measures like tool tethering and safety netting.

- Fatal Transportation Accident: This tragedy emphasized the need for comprehensive transportation safety programs, including driver training and vehicle maintenance.

The Role of Insurance in Mitigating Oilfield Accident Risks

Oil and gas insurance plays a crucial role in protecting companies from the financial impact of oilfield accidents. Different types of insurance coverage can help mitigate these risks:

- Liability Insurance: Protects against claims of bodily injury or property damage caused by company operations.

- Property Insurance: Covers damage to company assets, such as equipment and facilities.

- Workers’ Compensation Insurance: Provides benefits to employees who are injured on the job.

- Control of Well Insurance: Covers the costs associated with regaining control of a well blowout.

Having adequate coverage limits is essential to ensure that companies can recover from significant accidents. Read our detailed guide on oil and gas insurance to better understand this topic.

Future Trends in Oilfield Safety

The future of oilfield safety will be shaped by emerging trends:

- Increased Automation and Remote Operations: Continued advancements in automation and remote operations will further reduce human exposure to hazards.

- Greater Use of AI and Data Analytics: AI and data analytics will play an increasingly important role in predictive maintenance, risk assessment, and safety management.

- Focus on ESG Factors and Sustainability: Environmental, social, and governance (ESG) factors are driving a greater emphasis on sustainable and responsible oil and gas operations.

- Enhanced Cybersecurity Measures: Protecting OT systems from cyber threats will be a top priority to prevent physical accidents.

Conclusion

Oilfield accidents pose significant risks to human life, the environment, and business operations. By understanding the common types of accidents, their root causes, and the latest prevention strategies, companies can create a safer working environment. A proactive oilfield safety culture, combined with technological advancements and robust risk management practices, is essential for minimizing risks and preventing future incidents. Remember that oilfield safety is an ongoing effort that requires continuous improvement and adaptation. As mentioned, be sure to have adequate oil and gas insurance coverage to protect against potential financial losses from accidents.

FOR FURTHER READING:

- Explore some Best Practices for Oil and Gas Safety Compliance.

- Learn about The Role of Technology in Enhancing Oilfield Safety using Digital Twins, Robotics, and AI.

- Understand the benefits of Implementing Behavior-Based Safety Programs in Oil and Gas.

“`